Product Description:

Heat pump water heater works on principle just like an air conditioner or like the refrigerator. It absorbs warmth from the air and transfer it to heat water. Hence it’s also referred to as air-source heat pumps. It operates on electricity but is more efficient than a conventional electric water heater.

GOMON high-efficiency all in one heat pump water heaters provide an energy efficient and innovative water heating solution for your house.

Enamel Water Tank Brings You Healthier Water Quality

High pressure and fatigue resistance which pass 280,000 times pulse test.

High corrosion resistance because enamel coating makes the welding line of steel plate seperate with water, so with long working life.

Our Porcelain enamel tanks approved by CE, WATER MARK, ETL, WRAS, EN12977-3.

High efficient Micro-Channel Heat Exchanger

Larger heat exchange area, Better heat transfer effect and More durable performance.

The Coefficient of Performance of the system can reach 3.85 even above.

Not touch with water in the water tank, so the heat exchanger has no risk of corrosion, scaling, leakage, etc.

High Efficient Compressor

Being internationally-renowned brand dedicated compressor for heat pump, it is more reliable in system matching and quieter in operation.

Intelligent Defrosting

With intelligent defrosting design, it can revolutionarily solve the bottlenecks of heat exchangers in cold winter such as frosting and slow heating, etc., allowing you to spend a more comfortable winter.

1:1 Gold Ratio

The unit and water tank are matched with a gold ratio to eliminate the phenomenon of disharmony, so that it is more energy-saving and professional.

Intelligent Control Electric Expansion Valve

The electric expansion valve can control the refrigerant volume more accurately to ensure the unit stay in the best state.

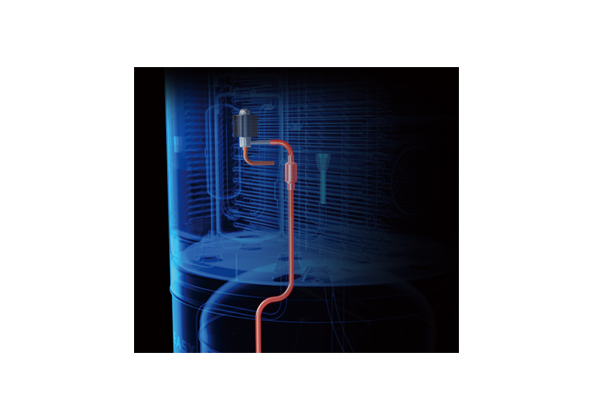

Smart and Convenient Touch Control

Intelligent light display

WIFI control

Real Images and Details:

Technical Parameters:

| Model | KRS35C-160V | KRS35C-200V |

| Tank Capacity | 160L | 200L |

| Inner Tank Material | Enamelled Steel (Steel BTC340R, 2.5mm thickness) | Enamelled Steel (Steel BTC340R, 2.5mm thickness) |

| Outer casing | Painted galvanized steel | Painted galvanized steel |

| Tank Rated Working Pressure | 0.8MPa | 0.8MPa |

| Waterproof grade | IPX4 | IPX4 |

| Condenser | Micro-Channel Heat Exchanger | Micro-Channel Heat Exchanger |

| Electric Element Power | 2000W | 2000W |

| Heat Pump Rated Input | 415W | 415W |

| Heat Pump Output | 1600W | 1600W |

| Max. Input Power | 2700W | 2700W |

| Heating Capacity | 35L/H | 35L/H |

| Max. Water Temperature | 75℃ | 75℃ |

| Voltage | ~220-240V / 50Hz | ~220-240V / 50Hz |

| Refrigerant | R134a | R134a |

| Energy efficiency Grade | Grade C | Grade C |

| Inlet / Outlet size | ¾” | ¾” |

| Control Method | Touch screen | Touch screen |

| Noise Level | 45dB(A) | 45dB(A) |

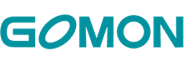

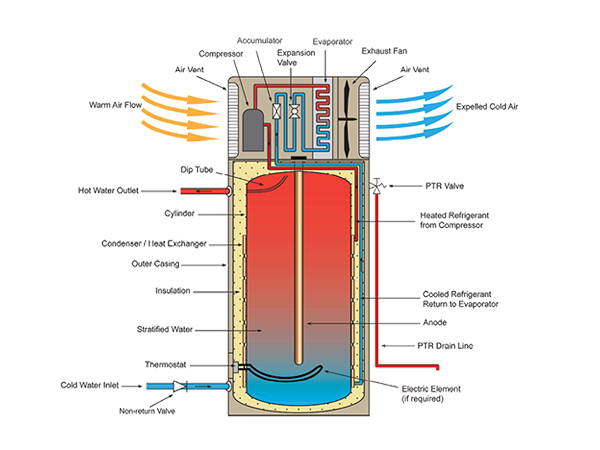

How It Works:

All in one heat pump water heaters are solutions where the domestic hot water is heated by an integrated heat pump

- The fan inhales ambient air transferring its energy to the refrigerant agent in the evaporator thus changing from liquid to gas.

- The gas is further heated by compression.

- In the condenser the gas transfers its accumulated heat to the water tank. As it gets colder it transforms back to fluid. The pressure of the fluid is further reduced by the expansion valve.

- The electric back-up heating starts only when required during insufficient heat pump working conditions.

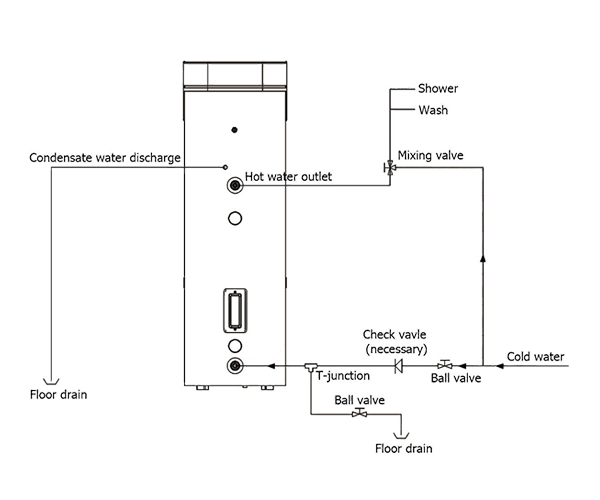

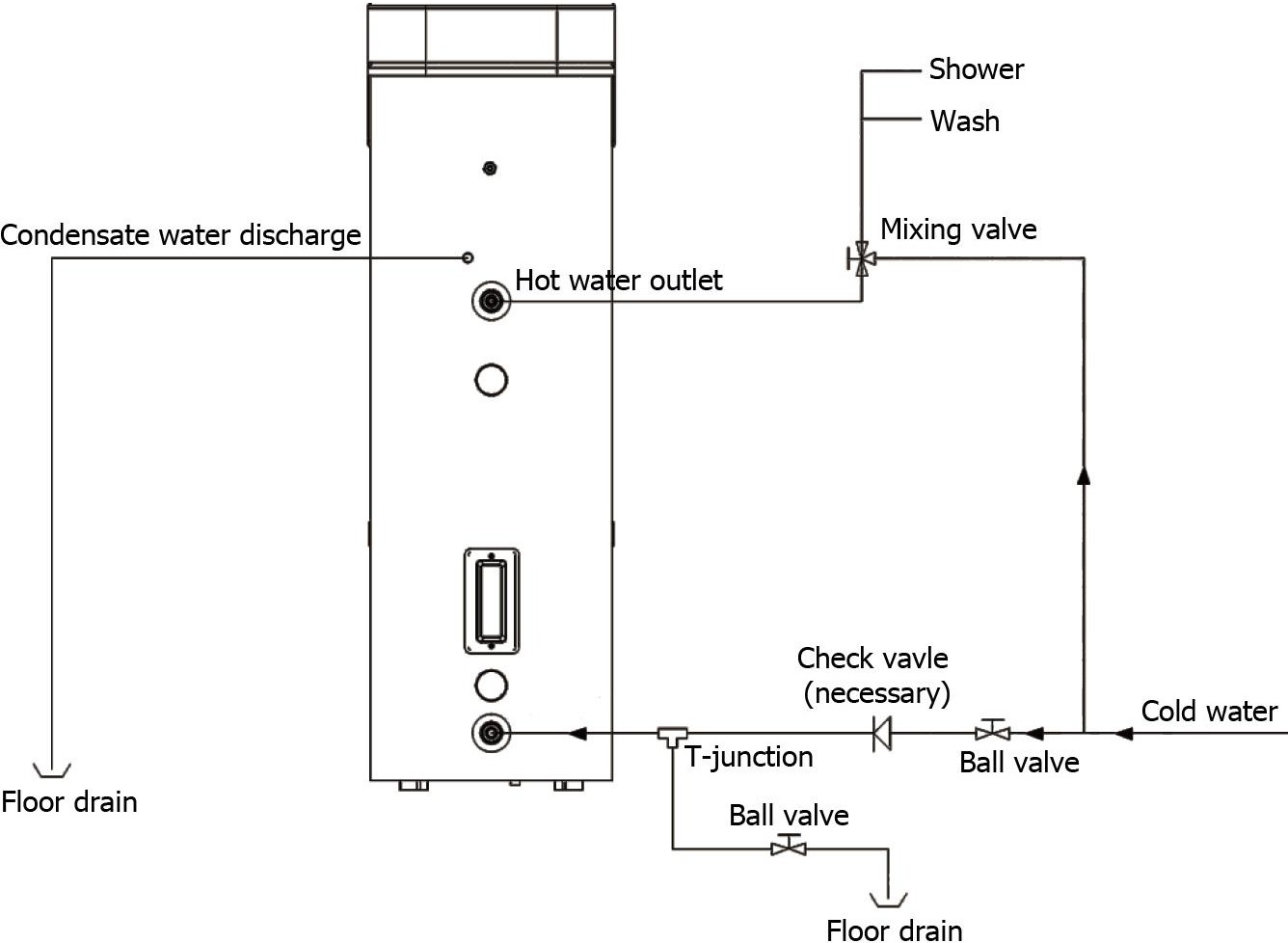

System Installation Diagram

Installation and Operation Manual:

- It is strictly prohibited to install, move or repair the water heater by yourself. Product installation and maintenance must be performed by the professional staff arranged by a local dealer or designated service outlet.

- It is strictly forbidden to pull the power cord, replace the power cord by yourself, or connect or lead the power cord halfway, otherwise electric shock or fire accident may occur.

- Please do not unplug the power cord during operation, or switch the machine by unplugging or plugging the power cord, which may cause damage to the equipment.

- When cleaning, maintaining and repairing the machine, please cut off the power switch and confirm that the fan has completely stopped before removing the air outlet. Do not wash the water heater with water, there is a risk of electric shock.

- Do not operate the power switch or plug with wet hands, there is a risk of electric shock.

- Be sure to unplug the power cord during a thunderstorm, or lightning may damage the water heater.

- When not in use for a long time, please cut off the power switch or unplug the power cord, otherwise an accident may occur.

- The inlet and outlet pipes and condensing drain pipes should be connected correctly to ensure no leakage. Condensing drain pipes should be installed at a downward slope in a frost-free environment and connected to the sewer pipe with adequate displacement in the building to avoid unnecessary losses.

- Please do not put fingers, sticks or other objects into the exhaust inlet and outlet of this water heater. Due to the high-speed operation of fans, injuries may be caused.

- If there is a refrigerant leakage during installation and maintenance, the room should be ventilated immediately. If the leaking refrigerant comes into contact with fire, toxic gas may be generated.

- Do not blow the exhaust inlet and outlet of the water heater directly to animals or plants, or it may cause bad influence.

- The water heater must be carried upright as indicated during transportation and handling, with the maximum allowable inclination not exceeding 15°.

- The equipment must remain upright for more than six hours before starting up and running; otherwise, the compressor will be damaged.

- It should confirm that there is no leakage in the pipeline after the installation; When the pipeline is installed, the one-way pressure relief valve and the sealing washer with filter screen must be installed correctly. The one-way pressure relief valve shall be adjusted to the unloading pressure not higher than 0.8MPa and manual discharge action shall be performed regularly (quarterly) to remove calcium carbonate deposits and prove that there is no blockage. Action method: pull the discharge handle upward to the horizontal position. If there is water flowing out of the pressure relief port, it is proved that there is no blockage. If there is no water flowing out, please restore the discharge handle and inform our maintenance personnel to repair it.

- During power-on heating, the safety valve may drip water, which is a normal phenomenon. Please note that the pressure relief port of the one-way safety valve is at a higher temperature and take care to avoid scalding the body. This pressure relief port must not be blocked, otherwise the pressure may not be normally discharged, resulting in water heater tank burst and water leakage.

- After all installation work is completed, the power can be connected after careful inspection and no fault is found. Before starting up, the water tank must be filled with water (open the water inlet and outlet valve, check whether water is discharged from the water faucet; if it is air discharge, please continue to discharge water until the water flow is stable).

- When the unit is in operation, the valve of the water inlet pipe of the water tank must be in the open state. When the tap water is cut off or stopped for a long time, the water tank must be full of water when the machine is re-started.

- If abnormal conditions are found, such as abnormal noise, smell, smoke, temperature rise, leakage, etc., please immediately cut off the power switch, and then contact the dealer or the designated service provider.

- The bar code on the equipment and the main parts is an important proof for you to enjoy the free warranty, which must not be damaged artificially, otherwise you will not enjoy the free warranty service of this machine.

- The ambient temperature range for the operation of the heat pump is 0°C to 43°C. Please set the appropriate temperature and it is recommended not to exceed 55°C. It is suggested to use the intelligent mode for automatic operation.

- Remove air blocking objects at air inlet and outlet to ensure that the air of the working environment can be fully exchanged with outdoor air, otherwise the energy efficiency of the water heater will be reduced.

- The water heater filter screen should be often cleaned, otherwise it will affect the heating effect. When cleaning, the power must be cut off first, and after confirming that the fan has stopped running, the filter can be removed, otherwise it may cause injury.

- At the beginning of use, please do not aim the nozzle at the human body and cold water must be mixed until it reaches the appropriate water temperature before use.

- During operation, the compressor can only start after about 3 minutes when the power is switched on again after shutdown and the operation mode is switched. This is the protection function set, but not the machine fault.

- All safety protection devices in the equipment have been set before delivery. Please do not adjust by yourself.

- Appliances should be installed in accordance with the national wiring rules, and fixed line must be equipped with a full-pole disconnecting device with at least 3 mm contact separation. If the power software is damaged, in order to avoid danger, it must be replaced by the manufacturer or maintenance department or similar full-time personnel. If the fuse wire of this equipment is disconnected, it must be replaced with 6.3A250V~ tubular fuse link by professional personnel.

- The equipment must be at least installed in the space size of 1.5*1.5*2.5 meters and the minimum allowable distance from the adjacent wall is 30 centimeters.

- Please ensure that the pressure of tap water is 0-0.8MPa and the inlet water temperature is 0°C-25°C.

- When water flows from the drain pipe of the pressure relief valve during overpressure, it is necessary to keep the drain pipe connected to the atmosphere and installed in a frost-free environment in a continuously downward manner.

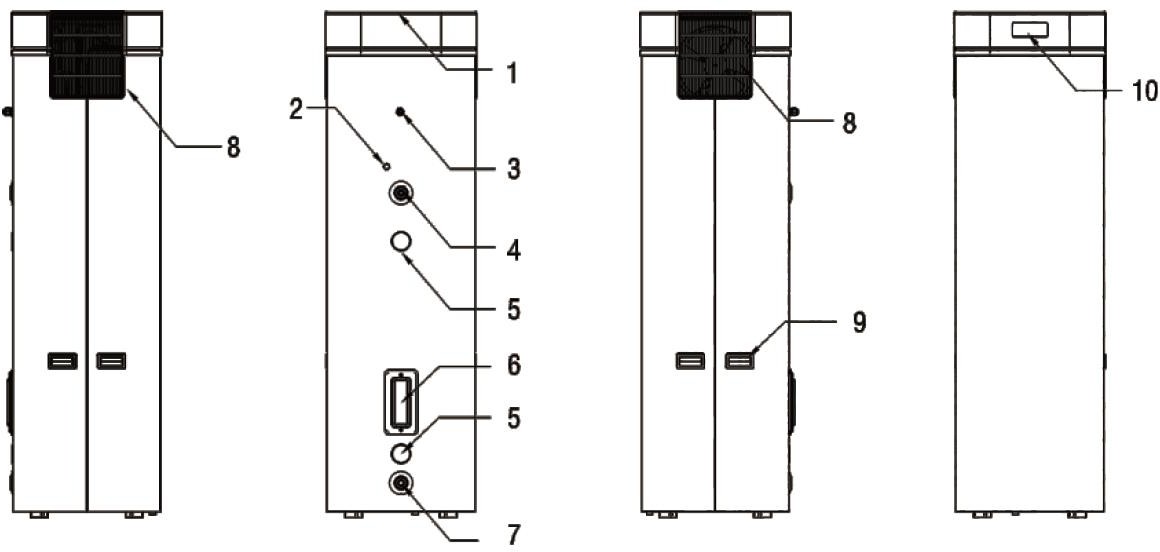

| 1. Top cover | 2. Condensate water nozzle | 3. Waterproof cable joint |

| 4. Hot water outlet | 5. Magnesium rod | 6. Electric heating element |

| 7. Cold water inlet | 8. Air inlet and outlet grille | 9. Handle |

| 10. Display screen |

Notes: All illustrations shown in this manual are based on the appearance of standard model air source water heater, only for the purpose of description of use. The actual appearance shall be subject to the model purchased.

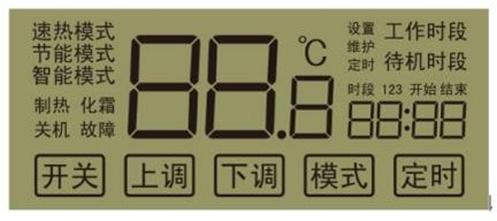

| 速热模式 Rapid heating mode | 节能模式 Energy saving mode | 智能模式 Intelligent mode | 定时 Timing |

| 制热 Heating | 化霜 Defrosting | 关机 Shutdown | 故障 Failure |

| 设置 Setting | 维护 Maintenance | 定时 Timing | 工作时段Working time period |

| 待机时段 Standby time period | 时段 Time period | 开始 Start | 结束 End |

| 开关 Switch | 上调 Up-regulate | 下调 Down-regulate | 模式 Mode |

Basic operation mode

On/off → mode → up/down → timing

1. Press the "on/off" button when starting the machine;

2. Press "mode" and select "rapid heating mode", "energy saving mode" or "intelligent mode";

① Under the "rapid heating mode", both air energy and electricity are used for heating at low water temperature, while only electricity is used for heating at high water temperature;

② Under the "energy saving mode", only air energy is used for heating at low water temperature, while electricity is used for heating at high water temperature;

③ Under the "intelligent mode", the air source water heater can automatically adjust and set the water temperature according to the ambient temperature. If the ambient temperature is lower, the water

temperature is set at 60°C; If the ambient temperature is higher, the water temperature is set at 55°C.

3. Press the "on/off" button again to stop the operation of the air source water heater.

Water temperature setting

On/off → mode → up/down → timing

Press the "up" and "down" buttons directly to enter the temperature setting state, press the "up" and "down" buttons to change the setting value (press the "up" button to increase 1°C once, and press the "down" button to decrease 1°C once). If there is no operation within five seconds, the current set temperature will be automatically defaulted and the temperature setting state will be exited.

Time setting

On/off → mode → up/down → timing

Press the "timing" button, and the hour part of the clock flashes. Press the "up" and "down" buttons to adjust the number of hours. After the adjustment, press the "timing" button to enter the minute setting. The same method is used to adjust the number of minutes. Press the "timing" button again for five seconds to exit the setting state of this time period.

Working time period setting of energy saving mode

On/off → mode → timing → up/down

Press "mode" button to switch to "energy saving mode", and then press "timing" button to enter the setting state of heating time period. Three groups of heating start time can be set in turn according to the instructions on the display screen (The "timing" button can be used to switch the heating period setting items, and the "up" and "down" buttons can be used to change the value). Three groups of heating time periods can be set at most. If it doesn’t need so many time periods, the start time and end time of the unnecessary time periods can be set as "00:00".

Notes:

- The above illustration is only a schematic diagram of the appearance, which may be somewhat different from the physical object you purchased. For example, some models are not set with a magnesium rod mounting port, circulation pipe port or sewage outlet; The sewage outlet or circulation port can be realized by adding a T-junction.

- Please install the safety valve at the water inlet end, and the maximum tightening torque of the safety valve shall not exceed 80N.M.

- For areas with severe thermonatrite and incrustation, it is necessary to install the pre-positioned water purification device, otherwise it may cause corrosion and damage to the storage tank. Too much incrustation will also affect the heating effect and water yield.

- Please keep the machine upright, preferably on a solid level ground (such as a corner of the balcony, etc.) to prevent it from toppling. If the machine is to be installed in an open place without any cover, reinforcement and waterproof/anti-radiation measures must be installed to prevent it from being blown down by high wind and getting wet by rain.

1. Preparation for installation

♦ Professional installers shall prepare installation tools, installation accessories and necessary measuring and qualified inspection instruments.

♦ Check whether the water heater is in good condition and whether the accompanying documents and accessories are complete.

♦ Read the instructions manual of this machine carefully to understand the functions, operation methods, installation requirements and methods of the water heater.

♦ Check the power supply of the customer, and 220V/50HZ ac power must be used.

① The electric connection of water heater generally adopts the dedicated branch circuit, and its capacity should be 1.5 times larger than the maximum current of water heater.

② The leakage protection device should be placed in a safe position that will not generate the risk of electric shock, especially to ensure that it is installed in a place that can not be splashed by water.

③ Check the separate fixed socket of water heater by means of visual inspection and special measuring device (power detector, test pen, grounding resistance meter, etc.) to ensure that the connection of live wire, zero wire and ground wire is correct, with reliable grounding.

④ Check whether the electric energy meters, wires and separate fixed socket capacity meet the requirements of the water heater carefully. This equipment is recommended to be equipped with power wire and fixed socket that can bear 25A, and 20A fuse shall be chosen.

♦ Check the pressure of tap water with the pressure gauge. If the tap water pressure is greater than 0.7MPa, a pressure relief valve needs to be installed in the water inlet pipe, which shall be as far away from the water heater as possible.

♦ Test the local water quality to ensure that the water used reaches the standard of neutral drinking water.

For areas with severe thermonatrite and incrustation, the pre-positioned water purification device must be installed at the user’s own expense, otherwise the water tank may be corroded and damaged. Too much incrustation will also affect the heating effect and water storage capacity.

♦ Assist the user to select the installation location of the water heater.

① The installation base should be solid to ensure that the installation surface can bear 2 times the weight of water heater filled with water, and plugin installation is strictly prohibited.

② Ensure the installation ground is level so as to be convenient to remove the condensate water and maintain the stability of the machine.

③ Convenient to install connecting pipe and electrical connection, and ensure that there is enough space for installation and maintenance.

④ This water heater must be installed on the solid level platform with dry air, shelter from rain and good ventilation, and wall plugin installation shall not be performed. If it is installed in airtight space, air inlet and outlet pipes must be installed to avoid the problems such as overflow of water, noise, indoor temperature drop.

⑤ It is suggested to be installed in the space with shelter from rain and ultraviolet such as balcony, and there should be no obstruction at the air inlet and outlet of equipment. If it is installed in the corner of wall, the air inlet and outlet must maintain 50 centimeters from the wall body.

⑥ If the equipment is installed in the metal part of the building, electrical insulation must be well performed, and the relevant standards of electrical equipment shall be satisfied.

⑦ Please do not install this water heater in places with humid environment and electromagnetic interference that may leak inflammable, explosive gas and corrosive gas.

⑧ Avoid places that are prone to resonance.

⑨ Try to shorten the length of connection between water heater and water point.

2. Installation and operation

♦ Professional installers should not randomly replace, omit or change the accompanying accessories used for the installation of air source water heater, and the additional devices to be installed must be equipped and installed in place according to the regulations.

♦ The safety guarantee structure of the building shall not be damaged during installation. The installation contact surface shall have sufficient bearing capacity.

♦ The pipes and fittings for users to install and connect must meet the national standards.

♦ In the water inlet pipeline must be installed with a one-way valve, the valve direction must be correct, the pressure relief port of the one-way pressure relief valve shall be installed downward, one end of the discharge pipe with a proper length shall be firmly installed on the pressure relief port of the pressure relief valve and the other end must lead to a floor drain to ensure smooth drain pipe without trap; meanwhile, enough maintenance space shall be reserved for convenient maintenance and repair in the future.

♦ The water inlet and outlet pipes should be well connected with reasonable direction, to ensure no leakage and good pipe insulation.

♦ After installation, this equipment shall be filled with water. Open any water tap at the water outlet (if a water mixing valve is installed, please rotate the handle of the water mixing valve to the high temperature position) of the equipment and then open the inlet valve; at this point, water starts to fill the equipment and it indicates that the equipment has been filled with water when water flows out from the water faucet uniformly; then, the water outlet faucet can be closed (or screw the handle of the water mixing valve to the closed position).

3. Inspection and trial operation

♦ Check the joints to ensure no leakage.

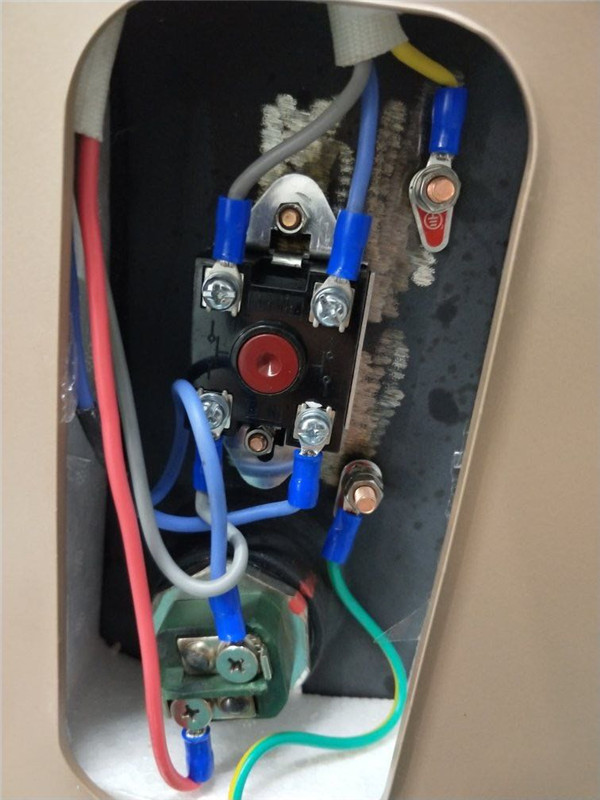

♦ Check the grounding effect of the fixed power socket, ensure that the current intensity carried by the socket and the wire is sufficient, with grounding wire and good grounding, and that the wiring positions of live wire, zero wire and ground wire are correct.

♦ Check the internal system: check whether the process pipe, compressor, evaporator, controller and other major components of the system are deformed or broken.

♦ Check the distribution system: check whether the power supply voltage is normal, whether the joint screw of each main power line is tightly locked, whether the line is distributed according to the distribution line requirements and whether the ground wire is connected well.

♦ Check the air source water heater: check whether all fastening screws and mechanical screws are loose.

♦ For the system installed with water inlet and outlet pipes, the water inlet and outlet pipes and condensate water drain pipes should be unblocked.

♦ Ensure that the equipment stands upright for more than 6 hours before plugging in the power and starting up for operation (set parameters according to the manual).

♦ Switch on the power and test the reliability of the leakage protection switch. The leakage protection plug should be tested before use and the test method is as follows: press the "reset" button, the indicator light is on after release, then press the "test" button, trip occurs and the indicator light is off, proving that the leakage protection plug can be used normally. After pressing the "reset" button, the indicator light is on and the equipment is powered on for operation. If it fails to trip and power off after pressing the “test” button, it indicates the leakage protection plug is damaged, and please replace it.

♦ Check the casing and places with possible leakage of electricity with a test pen or multimeter to ensure the water heater is safe and normal.

♦ Carefully check whether there is any abnormal phenomenon in the operation of the air source water heater. If there is abnormal sound, the power should be cut off immediately for inspection and the power can be switched on again only after the abnormality is eliminated.

Daily maintenance matters needing attention

Careful maintenance and early inspection can extend the service life of the equipment and save electric charge.

- For care and maintenance of the equipment, it is necessary to turn off the machine with controller first and then disconnect the

- During care and maintenance of the equipment, do not stand on the unstable table surface, otherwise the table will tilt and cause

- In principle, the user shall not open the machine casing himself or touch the machinery fin and other accessories under the condition that the machine casing is opened by the professional maintenance staff, otherwise it will lead to

- Please ask professional staff to clean the filter screen of air inlet at your own expense regularly, and clean it with clean water after disassembly according to the dust

- After two years of use, the magnesium rod will wear out naturally and needs to be replaced As the magnesium rod is a natural consumable protection product, it needs to be replaced at your own expense to ensure the service life of the storage tank. If the magnesium rod is not replaced regularly, the damage of the storage tank is not covered by the warranty.

- Clean the heating storage tank regularly:

- To ensure the quality of your hot water, please follow the steps below to clean the heating storage tank

① Close the inlet ball valve;

② Open the sewage ball valve;

③ Open the hot water faucet at the user end, and empty the water in the water storage tank;

④ Close the sewage valve, open the inlet ball valve, wash the water storage tank and then open the sewage valve; Rinse repeatedly until the water from the sewage outlet is clear;

⑤ After cleaning the water storage tank, open the water inlet and outlet valve until the hot water intake can normally and evenly discharge water.

- Regularly check whether the power cord of the equipment is in good condition and whether the leakage protection plug works If there is any problem, please contact the local dealer.

Care and maintenance of electrical parts

Please wipe the power cord and the display screen directly with a dry soft cloth. If there is dirt that cannot be wiped away, wipe it with a soft cloth dipped in neutral detergent and meanwhile pay attention to the following matters:

- Do not clean the unit with If water enters the air source water heater, it will lead to malfunction of the air source water heater, electric shock and other accidents.

- The equipment can be wiped with wrung wet soft

- When cleaning the panel, please do not apply too much force, or the panel may be

- Please do not wipe the panel with wire netting ball, brush, etc., otherwise the casing will be damaged.

- Do not use alcohol, gasoline, lacquer thinner, polishing powder and other chemicals and solvents to clean the equipment, because these substances will damage the

Please do the following work before the equipment is idle for a long time

- Disconnect the power

- Empty the water storage tank and pipeline and close each valve

- The internal components of the unit should be inspected and cleaned Please contact the local dealer.

After being idle for a period of time, the equipment should be checked before

- Check the air inlet and outlet of the machine, and timely clean the dust that affects normal use and remove the foreign matters that block the air inlet.

- Check whether the pipeline and valve body of the water storage tank are damaged or blocked, whether the interfaces are leaking, whether the main engine is emitting abnormal sound, etc. If necessary, deal with it

Fault analysis

Faults and causes of air source water heater

| Fault state | Possible causes of fault | Disposal measures |

| The unit doesn’t work | Power failure Loose power connection of the unit Control power fuse blow of the unit | Disconnect the power switch and check if the power supply is energized Reconnect the power Replace with a new fuse |

| The heating capacity of the unit is low | Insufficient refrigerant Poor insulation of pipe Poor heat dissipation of air heat exchanger Filter screen clogging | Perform leakage detecting and fill refrigerant Strengthen insulation of water circulation pipe Wash the air heat exchanger Clean the filter screen |

| The compressor doesn’t work | Power failure Damage of the compressor relay of electronic control mainboard Loose wire connection Overheating protection of compressor | Identify the cause and solve the power failure Replace the controller Identify the loose spots and fix them Find out the cause of overheating and turn on the machine after troubleshooting |

| The compressor runs with a large noise | Insufficient lubricating oil Damage of the internal parts of compressor | Add lubricating oil Replace the compressor |

| The fan doesn’t work | The fastening screw of the fan is loose The fan motor is burnt out The fan relay or capacitor of the main control board is damaged | Fasten the screw Replace the fan Replace the controller and capacitor |

| The compressor runs without heating | Refrigerant leakage Compressor failure | Perform leakage detecting and fill it with a standard dosage of refrigerant Replace the compressor |

| Excessive exhaust pressure | Excessive refrigerant There is air in the system | Discharge excess refrigerant Re-vacuum and fill refrigerant |

| Low inspiratory pressure | Insufficient system refrigerant Filter clogging | Fill refrigerant quantitatively Replace the filter |

Special symbol description

| Name | Symbol | State | Function or meaning |

| Shutdown symbol | Shutdown | Normally on | It is currently in the shutdown state |

| Heating symbol | Heating | Normally on | Being heated |

| Heating symbol | Heating | Flickering | Heating delay |

| Defrosting symbol | Defrosting | Normally on | Being defrosted |

| Defrosting symbol | Defrosting | Flickering | Defrosting start or end delay |

| Defrosting symbol | Defrosting | Flickering | Refrigerant filling or recycling |

| Warning symbol | Fault | Normally on | An alarm is currently taking place |

| Rapid heating mode symbol | Rapid heating mode | Normally on | Control the temperature of the water according to the rapid heating mode |

| Energy saving mode symbol | Energy saving mode | Normally on | Control the temperature of the water according to the energy saving mode |

| Intelligent mode symbol | Intelligent mode | Normally on | Control the temperature of the water according to the intelligent mode |

| Timing control symbol | Timing | Normally on | It is currently in the timing control mode |

| Working time period symbol | Working time period | Normally on | It is currently in the timing working time period |

| Standby time period symbol | Standby time period | Normally on | It is currently in the standby time period |

| Time period 1 symbol | Time period 1 | Normally on | Set the time of time period 1 |

| Time period 2 symbol | Time period 2 | Normally on | Set the time of time period 2 |

| Time period 3 symbol | Time period 3 | Normally on | Set the time of time period 3 |

| Time period start symbol | Start | Normally on | Set the start time of the working time period |

| Time period end symbol | End | Normally on | Set the end time of the working time period |

| Celsius symbol | °C | Normally on | The current display is in Celsius |

| Setting symbol | Setting | Normally on | It is currently in the parameter setting state |

| Maintenance symbol | Maintenance | Normally on | It is currently in the maintenance mode |

System fault codes, causes and disposal measures

| Code | Causes | Actions |

| Err | Data access fault | None |

| E01 | Fault of water temperature sensor of heat pump | Use the electrically heated water temperature control heat pump for heating |

| E02 | Fault of electrically heated water temperature sensor | Use heat pump water temperature display and stop using the heating function |

| E03 | Fault of temperature sensor | Fault of ambient temperature-related functions |

| E04 | Fault of exhaust temperature sensor | Fault of exhaust high temperature protection function |

| E05 | Fault of coil temperature sensor | Defrost according to the set way and open the electronic expansion valve to the initial opening |

| E06 | Fault of suction temperature sensor | Open the electronic expansion valve to the initial opening |

| E11 | Excessive pressure alarm | Suspend the use of compressor heating or lock the controller |

| E12 | Low pressure alarm | Suspend the use of compressor heating or lock the controller |

| E21 | Exhaust high temperature protection | Suspend the use of compressor heating |

| — | The communication between the hand-operated panel and the main control board is abnormal. | The main control board works according to the set parameters |

| —:一 | Clock malfunction | In the timing control mode, it is considered to be in the working time period |

Package

We participate in the recycling programs of various countries to ensure optimal recycling. All our packaging materials are environmentally friendly and recyclable.

Old equipment

The old equipment containing valuable materials should be recycled. These components can be easily separated and composited and also marked accordingly. Therefore, these components can be classified and further recycled or disposed of.

Prior to the end of the service life of this equipment, the personnel who have operational qualifications to the refrigeration circuit must recycle the refrigerant from the sealing system based on the preferred consideration of environmental protection.